ES400H3

Industrial

Electrospinning & Electrospraying System

ES400H3 Industrial Electrospinning & Electrospraying System

Scalable Electrospinning Platform for R&D and Industrial Manufacturing

Overview

The ES400H3 is a high-performance electrospinning and electrospraying system designed to bridge the gap between laboratory research and industrial-scale production. With support for processing volumes ranging from sub-milliliter to multi-liter, the ES400H3 enables scalable and repeatable manufacturing of nanofibers and micro/nanoparticles for applications in medical devices, pharmaceuticals, membranes, and advanced materials .

Its modular architecture, multi-emitter capability, and wide range of interchangeable collectors allow precise optimization of fiber deposition and uniformity across flat substrates, membranes, coatings, and composite structures.

Its modular architecture, multi-emitter capability, and wide range of interchangeable collectors allow precise optimization of fiber deposition and uniformity across flat substrates, membranes, coatings, and composite structures.

Key Features

Multi-Emitter High-Voltage Architecture

- 3 independent emitter systems

- 3 adjustable high-voltage power supplies (0–40 kV)

- Collector voltage up to –20 kV

- Smart spark detection and over-current protection

- Voltage resolution of 0.1 kV for fine process control

This configuration enables simultaneous multi-channel processing for higher throughput and improved reproducibility.

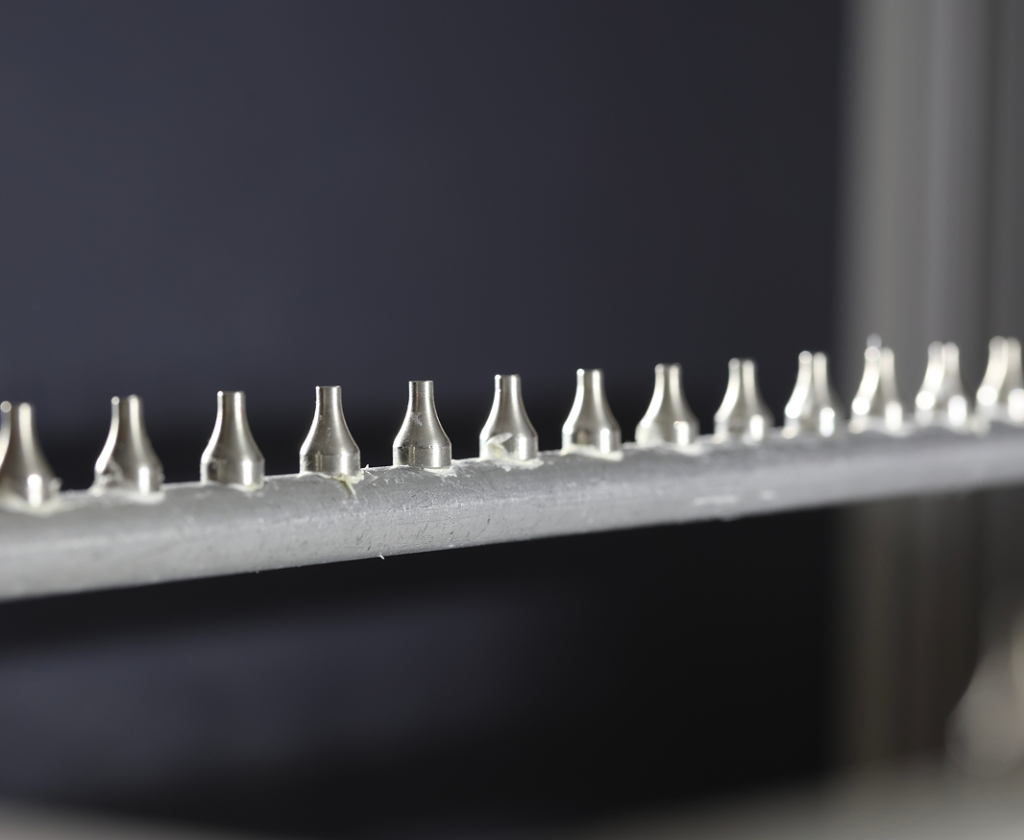

Advanced Spinneret Configurations

The ES400H3 supports needle-based and needleless electrospinning, fully interchangeable depending on process needs:

- Nozzle-based spinnerets: 3 × 400 mm pipes, supporting up to 9 nozzles per pipe

- Single-needle spinnerets: 3 × 200 mm rods, supporting up to 3 needles per rod

- Needleless option: TurboSlit injector with 150 mm slit width (optional)

This flexibility allows users to move seamlessly from precision R&D work to higher throughput production.

Modular Collector Platform

The ES00H3 Features A Fully Modular Cpllector System, Supporting Multiple Production Modes:

- Ø100 mm × 400 mm

- Up to 1000 RPM for controlled alignment

- Ideal for batch and coating processes

- tainless steel conveyor

- Membrane size up to 1600 × 400 mm

- Line speed: 1–100 mm/min

- Working width: 400 mm

- Bidirectional operation

- Advanced tension control

- Substrate speed: 1–100 mm/min

- Core diameter: 75–80 mm

Precision Feeding System

The system supports both syringe-based and continuous feeding:

- Flow range: 0.01 mL/h – 3400 mL/h

- Reservoirs up to 60 mL

- Continuous, pulsation-free feeding

- Up to 2 L solution volume

- Flow rate up to 100 mL/min

This dual feeding capability enables both formulation development and long-duration production runs.

Environmental & Atmospheric Control

Temperature

Control

- 3 × 800 W heaters

- Chamber temperature up to 45°C

Inert Gas

System

- Nitrogen operation (< 30 L/min)

- Reduces oxygen concentration

- Enhances safety with flammable solvents

- Improves process stability and uniformity

Humidity

Control

- Dehumidification capacity: 2.2 kg/h

- Achievable humidity down to ~10% RH

- In-Line Homogeneity & Thickness Control

- Linear motion homogeneity system

- Speed up to 20 mm/s

- Stroke up to 80 mm

- In-line thickness monitoring for real-time deposition control

- User Interface & Automation

- 12-inch touchscreen HMI

- Parameter storage and recall

- Repeatable recipe-based operation

- Designed for both R&D users and production operators

- Safety & Compliance

- Fully sealed cabinet with solvent vapor exhaust

- Automatic HV shutdown when doors open

- Safety interlock system

- Emergency stop and warning indicators

- Fully grounded chassis

- Integrated spark detection

- System Dimensions & Utilities

- Dimensions: 1200 × 900 × 2050 mm

- Approx. weight: 300 kg

- Total power: 6 kW

- Machine: 1.5 kW

- Heaters: 2.5 kW

- Dehumidifier: 2.0 kW

Applications

- Drug delivery systems

- Medical & pharmaceutical membranes

- Functional coatings

- Filtration and separation membranes

- Composite and multilayer nanofiber structures