Electrospinning

Machine

ES800H4

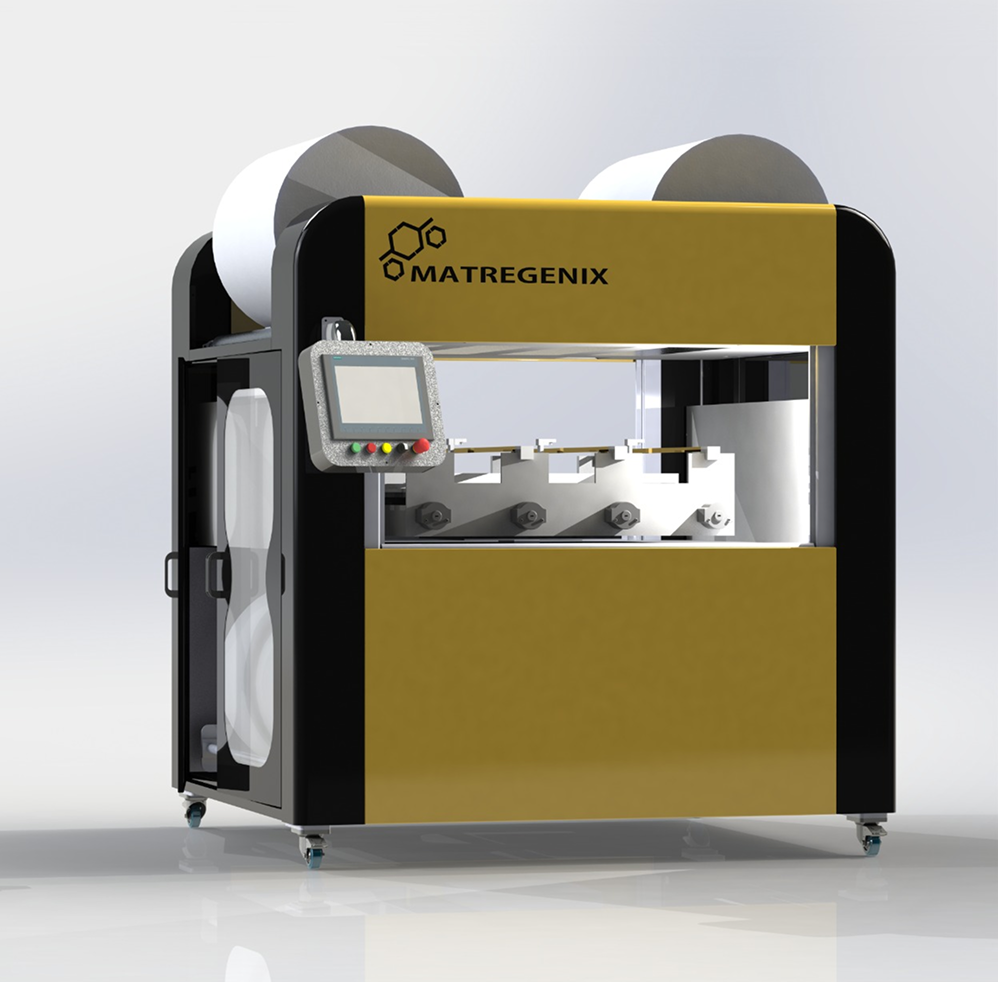

Industrial Electrospinning Machine ES800H4 Needleless Turbo / Needle-Based

Overview

For large-scale production, our industrial Electrospinning Machine ES800H4 is designed to meet high-volume demands with advanced technology. This machine features a modular spinneret system that supports both needle-based and needleless (Turbo) technologies. The Turbo technology utilizes a moving head that feeds a slit spinneret electrode connected to high voltage, allowing nanofibers to form from the thin polymer layer on the spinning electrode, making it an exceptional choice for industrial nanofiber electrospinning.

Key Features

800Mm

Roll-to-Roll Collector

(Customizable up to 1600 mm)

Designed for continuous production, the roll-to-roll system allows seamless fabrication of nanofiber membranes with tailored widths for large-scale applications.

Needleless

High-Productivity

Spinneret

The machine supports high-efficiency needleless electrospinning, significantly increasing output while maintaining uniform fiber distribution.

High Productivity

with Low Power

Consumption

Optimized for energy efficiency, this machine maximizes nanofiber production while minimizing operational costs.

Machine Features

- Roll-to-roll collector for continuous production

- Up to 120 kV applied voltage

- Nozzle & nozzle-free (TURBO) modular spinneret systems

- Advanced homogeneity system

- Integrated climate control

- Continuous feeding peristaltic pumps

- Tailored roll width (up to 1600 mm)

- Additional slot for lamination/scrim layers

- Safety functions and sealed chamber

Optional Custom Features

- Heater and dehumidifier

- Online air permeability tester

- Flat collector plate

- Vacuum collector

- Gas-assisted nozzle

- UV lamp for drying

- Bicomponent nozzle

- Syringe pumps

- Gas shield

- HEPA filter

- Taylor cone visualization camera

- External heating and dehumidification system

Filtration &

Separation

Production of high-performance nanofiber membranes for air and liquid filtration.

Medical Devices

Electrospun scaffolds for tissue engineering and wound dressing applications.

Batteries &

Fuel Cells

High-surface-area nanofibers for energy storage and conversion applications.

Food Packaging

Biodegradable nanofiber coatings for enhanced food safety and preservation.

Environmental Remediation

Advanced materials for pollution control and water purification.

The industrial electrospinning machine is an advanced system designed for high-volume nanofiber production with superior control and flexibility. Its modular design, high-voltage capabilities, and integrated environmental control make it the ideal solution for large-scale applications.