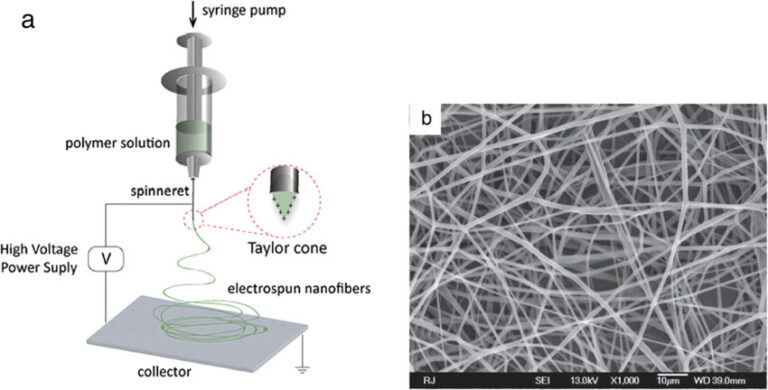

Ever wondered how nanofibers are made in a real production environment? This blog takes you behind the scenes of a typical nanofiber lab and walks you through each step of the process—from polymer solution preparation to fiber collection. It explains how machines are calibrated, how safety protocols are maintained, and how quality metrics are monitored. Using electrospinning as the core technique, the blog highlights the importance of voltage control, flow rate, temperature, and humidity in achieving precise fiber characteristics. Readers will also learn about post-processing methods such as drying, layering, and fiber treatment, which are essential for commercial applications. Whether you’re a researcher setting up a lab or a buyer looking to understand production capabilities, this article paints a clear, practical picture of how nanofibers go from liquid to functional material. It’s an ideal guide for understanding operational challenges, workflow optimization, and scalability in nanofiber production.

Inside a Nanofiber Production Lab: A Step-by-Step Look at the Process